Tyrolean's cracked render can be more than just an aesthetic issue; it often indicates underlying problems that can compromise the integrity of your building.

Understanding what causes this type of render damage is crucial for effective prevention and repair.

This article explores the causes of Tyrolean's cracked render, how to identify it, the risks of leaving it unrepaired, and the tools and materials needed for successful repairs.

Additionally, it discusses alternatives and preventative measures to help maintain your property’s appearance and durability, such as using polymer-modified adhesives and bonding primers.

Whether you’re a homeowner or a DIY enthusiast, this guide provides the knowledge needed to tackle Tyrolean cracked render confidently, using the right techniques and tools.

Table of Contents

Tyrolean cracked render is a specialised exterior render used in the UK that features a unique textured finish, often employed for aesthetic renovation on buildings. This application is not only about enhancing visual appeal; it also serves a protective function against moisture levels and weather damage.

Understanding the nuances of Tyrolean cracked render, including its types and characteristics, is essential for homeowners and professionals alike to ensure the longevity and structural integrity of their properties. Regular inspection and maintenance of this render can prevent further damage and complications. Regular inspection and maintenance of this render can prevent further damage and complications.

Explore further: What Is Tyrolean Rendering

The causes of Tyrolean's cracked render can be attributed to various factors, including poor application techniques, extreme weather conditions, and structural movement. Understanding these underlying issues is crucial for homeowners and professionals to properly assess and address the damage caused to the render.

Each of these factors contributes differently to the occurrence of cracks, impacting the longevity and effectiveness of the render as a protective barrier. Identifying these causes early on can lead to more effective repair techniques and better overall maintenance.

Poor application techniques are among the primary causes of Tyrolean's cracked render, stemming from inadequate surface preparation and the improper use of tools, materials, and safety equipment like safety goggles and gloves.

These issues can compound, leading to a situation where the integrity of the finish is compromised and the aesthetic appeal is lost. For instance, when the wrong type of trowels is selected, or when fillers are improperly applied without smoothing out imperfections, it becomes nearly impossible to achieve a flawless surface. Inadequate attention to the mixing process can result in a substandard consistency, causing the render to weaken over time.

By adhering to these specific application techniques, one can effectively mitigate the risk of developing cracks and ensure a long-lasting, visually appealing render. Using pre-mixed solutions like Toupret or Chemfix can simplify the process.

Extreme weather conditions significantly contribute to the cracking of Tyrolean render, as fluctuations in temperature and excessive moisture can cause the render to expand and contract, leading to both aesthetic and structural damage. This relentless cycle of stress can lead to structural damage over time, which may necessitate urgent repair efforts. Prolonged exposure to moisture can compromise the integrity of the render, leading to further aesthetic and structural concerns.

Weather elements, particularly heavy rain, can saturate the render, making it more susceptible to deterioration. High humidity adds another layer of risk, creating a breeding ground for mould and mildew, which can further exacerbate the damage.

In regions where extreme temperatures are prevalent, such as freezing winters or sweltering summers, the render undergoes significant stress as it struggles to cope with such drastic changes.

Over time, these conditions can result in structural concerns that demand immediate attention to preserve both appearance and functionality.

Consulting a structural engineer is often recommended to properly assess the extent of the damage.

Structural movement is another critical factor contributing to Tyrolean cracked render, as it can create stress points that lead to damage over time. Factors such as settling foundations or shifts in building materials can exert significant pressure on the render, resulting in cracks and other visible signs of wear. Regular inspection and maintenance are vital to identify early signs of structural movement that may compromise the integrity of the render.

This movement often goes unnoticed until it manifests as surface damage, making it essential for property owners to remain vigilant. Tyrolean renders require periodic assessments to catch signs of deterioration, such as hairline fractures or flaking. Evaluating these signs promptly can prevent costly repairs.

A structured inspection plan could include:

Implementing maintenance strategies such as flexible sealants can mitigate the effects of minor shifts, ensuring the longevity and aesthetics of the render. Professionals often recommend products like Fibacryl or Metoset for their reliability. By prioritising these efforts, one can significantly reduce the risks associated with structural movement.

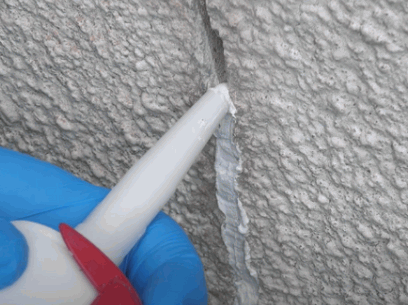

Identifying Tyrolean cracked render involves a systematic inspection process to detect various types of cracks and assess the extent of damage caused by existing moisture or other environmental factors.

Homeowners should look for signs such as hairline cracks, map patterns, and other anomalies in the render surface. Map patterns are particularly concerning as they indicate widespread issues. Using the correct tools for inspection, such as a scraper or a hammer, can help determine the severity of the damage and whether professional expertise is required.

Leaving Tyrolean cracked render unrepaired poses significant risks to both the aesthetic and structural integrity of a building. Over time, unaddressed cracks can allow moisture ingress, leading to further damage and potential structural issues that may require professional intervention.

The consequences of neglecting these repairs can escalate quickly, resulting in costly renovations and decreased property value.

Repairing Tyrolean cracked render requires both basic and specialised tools to ensure a successful restoration process. Essential tools include:

Repairing Tyrolean cracked render requires a variety of specialised tools to ensure a successful restoration process. Essential tools include:

Understanding the role of each tool in the repair process is crucial for achieving a smooth and lasting finish.

Repairing Tyrolean cracked render involves a systematic process that includes cleaning, filling with materials like mortar or polymer-modified adhesive, and applying a new coat of render to restore both the aesthetic and structural properties.

This process begins with assessing the damage and ensuring a clean surface free from existing moisture, followed by the application of filler to smooth out the cracks. Once filled, a new coat of render may be applied, ensuring that the surface is adequately cured to prevent future cracking.

The first step in repairing Tyrolean's cracked render is to thoroughly clean and prepare the surface, ensuring that all existing moisture and debris are removed. This foundational process lays the groundwork for a successful repair, as any leftover contaminants can significantly impact the effectiveness of the repair materials.

Cleaning involves several essential steps:

By systematically completing these tasks, you pave the way for optimal adhesion and durability of the filler, ultimately enhancing the longevity of the repair. Products like Fibacryl and Metoset are great options for fillers due to their durable properties.

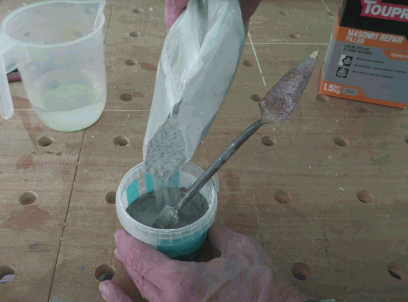

Filling in the cracks of Tyrolean render is a critical step that involves using a suitable filler or mortar to create a seamless surface. Experts often recommend using a polymer-modified adhesive for better performance. The application should be done carefully, using a trowel to ensure that the filler is applied evenly and adequately smoothed out to match the surrounding render. This step is essential to restore both the aesthetic and structural integrity of the render.

To achieve a flawless finish, one must choose the right type of filler; for instance, a crack filler with a polymer base often works best for enhanced adhesion and flexibility. Always follow the manufacturer's guidelines for the best results.

Once applied, a second layer may be needed after the first has dried, followed by light sanding to achieve the desired smooth finish on the masonry surface. By taking these careful steps, it is possible to ensure that the repairs blend seamlessly with the existing texture, significantly enhancing the overall appearance.

After filling in the cracks, the next step is to apply a new coat of Tyrolean render to restore the aesthetic appeal and functionality of the surface. This involves using the right mixture to ensure consistency and effective bonding and applying it smoothly with a trowel for an even finish. Proper application techniques are vital to achieve the desired look and durability of the render.

To begin with, achieving the right mixture consistency is crucial; it should neither be too thick nor too runny, allowing it to adhere properly without sagging. When preparing the mixture, consider the following guidelines:

Next, selecting the appropriate tools enhances the process, with a trowel being essential for applying the render evenly. Employing the right application techniques—such as using smooth, consistent strokes and maintaining a steady pressure—will lead to a professional-looking finish. Always remember to work in sections to allow better control and ensure a uniform coat throughout the surface.

When faced with Tyrolean cracked render, homeowners may consider several alternatives to traditional repair methods, including innovative solutions like using Fibacryl for added flexibility, including removing the existing render completely or covering it with new material.

Each option has its pros and cons, depending on the extent of the damage, budget, and desired aesthetics. Understanding these alternatives is essential for making informed decisions about maintaining the property's exterior, such as consulting experts.

Completely removing the Tyrolean render is a more extensive approach that may be necessary for severe damage or aesthetic updates. This process requires specialised tools and careful execution to ensure that the underlying surface is not harmed. Proper preparation and understanding of the underlying structure are crucial to prevent future issues.

When tackling the removal of Tyrolean render, it’s essential to begin your project with a clear plan and the right equipment at hand. Here’s a brief overview of what you’ll need:

Begin by assessing the area to safely identify any underlying electrical or plumbing systems. Next, protect surrounding areas from debris by covering them with dust sheets.

Start removing the render gently from the top down, using a chisel or electric tool while ensuring to wear safety gear to minimise dust exposure. Following these steps carefully will help maintain the integrity of the wall beneath.

Covering cracked Tyrolean render with a new material offers a quick solution that can enhance both appearance and functionality, particularly enhancing the Tyrolean finish.

This method often employs polymer-modified adhesive to bond the new material securely over the existing render, providing an aesthetically pleasing finish while improving moisture resistance. Additionally, the choice of material significantly influences the overall outcome, so understanding the options is crucial.

For instance, options include:

Using these materials not only revitalises the visual appeal but also extends the lifespan of the structure, ultimately leading to reduced long-term maintenance costs.

Preventing Tyrolean cracked render involves employing effective application techniques and maintaining regular inspections to identify potential issues before they escalate.

Properly preparing the surface, using high-quality materials such as epoxy products, and being mindful of environmental conditions can significantly reduce the likelihood of cracks forming. Regular maintenance inspections play a crucial role in ensuring the longevity and durability of the render.

Using proper application techniques is fundamental in preventing the occurrence of Tyrolean cracked render, as inadequate surface preparation can lead to failures. Ensuring that the surface is clean, applying a bonding primer, and using the right tools are essential steps in achieving a successful application that stands the test of time.

To achieve an optimal finish, it is crucial to follow a systematic approach.

Implementing these essential techniques will significantly reduce the likelihood of cracking and contribute to the longevity of the render.

Regular maintenance and inspections are key strategies in preventing Tyrolean cracked render by allowing for the early detection of damage and moisture issues. Scheduling routine inspections helps homeowners assess the condition of the render and address any concerns before they escalate into major problems.

To effectively safeguard the integrity of your property, homeowners should establish a consistent maintenance schedule, ideally conducting these checks at least twice a year. During inspections, look for signs of cracking, peeling, or discolouration, as these could indicate underlying moisture problems. It's also wise to:

Implementing these best practices can significantly enhance the durability of the render, ultimately saving time and money while preserving the aesthetic appeal of the home.

Protecting Tyrolean cracked render against extreme weather conditions is vital for maintaining its integrity and preventing damage. Implementing protective measures such as overhangs, drainage systems, and moisture barriers can help shield the render from harsh environmental factors that can lead to cracking.

To enhance the durability of the render, it is essential to consider multiple protective strategies. For instance, installing rainwater drainage systems not only directs water away from vulnerable surfaces but also mitigates the risk of moisture accumulation. Likewise, the construction of shaded overhangs serves a dual purpose—providing shelter from rain and reducing sun exposure, thus minimising overheating.

Ultimately, taking these precautions will significantly contribute to preserving the aesthetics and functionality of the render.